Energy Star

The

Energy Star service mark is placed on energy-efficient

products.

Energy Star (trademarked ENERGY

STAR) is an international standard for energy efficient consumer products originated in the

United States of America. It was created in 1992 by the Environmental

Protection Agency and the Department

of Energy during the Clinton

Administration. Since then, Australia, Canada,

Japan, New Zealand, Taiwan and the European Union have adopted the program.

Devices carrying the Energy Star service mark, such as computer products and

peripherals, kitchen appliances, buildings and other products, generally use

20%–30% less energy than required by federal standards.

History

The Energy Star program

was developed by John

S. Hoffman, inventor of the Green Programs at EPA, working closely

with the IT industry, and implemented by Cathy Zoi and Brian Johnson.The program was intended to be part

of a series of voluntary programs, such as Green Lights and the Methane

Programs, that would demonstrate the potential for profit in reducing energy

consumption and greenhouse gases by power plants.

Initiated as a voluntary

labeling program designed to identify and promote energy efficient products,

Energy Star began with labels for computer and printer products. In 1995 the

program was significantly expanded, introducing labels for residential heating

and cooling systems and new homes. As of 2006, more than 40,000

Energy Star products are available in a wide range of items including major

appliances, office equipment, lighting, home electronics, and more. In

addition, the label can also be found on new homes and commercial and

industrial buildings. In 2006, about 12 percent of new housing in the United States was labeled Energy Star.

The EPA estimates that

it saved about $14 billion in energy costs in 2006 alone. The Energy Star

program has helped spread the use of LED traffic lights, efficient fluorescent lighting, power management systems for office

equipment, and low standby energy

use.

In 2008, the EPA

announced Green Power Partnership program, which was designed to help achieve

its goal of encouraging the use of renewable power sources. The renewable

energy credits allow companies without direct access to renewable power achieve

their goals. However, to avoid companies buying RECs years in advance of any of

the hypothetical power ever being produced, RECs are only accepted into the

program when the actual equivalent renewable power will be produced.

Specifications

Energy Star

specifications differ with each item, and are set by either the Environmental

Protection Agency or the Department of Energy. The following highlights product

and specification information available on the Energy Star website.

Computers

Energy Star 4.0

specifications for computers became effective on July 20, 2007. The

requirements are more stringent than the previous specification and existing

equipment designs can no longer use the service mark unless re-qualified. They

require the use of 80 Plus Bronze

level or higher power supplies.

Energy Star 5.0 became effective on July 1, 2009.

Servers

The EPA released Version

1.0 of the Computer Server specifications on May 15, 2009. It covers standalone

servers with one to four processor sockets. A second tier to the specification

covering servers with more than four processor sockets, as well as blade

servers and fault-tolerant machines is expected in 2012.

Appliances

As of early 2008,

average refrigerators need

20% savings over the minimum standard. Dishwashers need at least 41% savings.

Most appliances as well as heating and cooling systems have a yellow

EnergyGuide label showing the annual cost of operation compared to other

models. This label is created through the Federal Trade Commission and often

shows if an appliance is Energy Star. While an Energy Star label

indicates that the appliance is more energy efficient than the minimum

guidelines, purchasing an Energy Star labeled product does not always mean you

are getting the most energy efficient option available. For example,

dehumidifiers that are rated under 25 US pints (12 L) per day of water

extraction receive an Energy Star rating if they have an energy factor of 1.2 (higher is better),

while those rated 25 US pints (12 L) to 35 US pints (17 L) per day

receive an Energy Star rating for an energy factor of 1.4 or higher. Thus a

higher-capacity but non-Energy Star rated dehumidifier may be

a more energy efficient alternative than an Energy Star rated but

lower-capacity model. The Energy Star program's

savings calculator has also been criticized for unrealistic assumptions in its

model that tend to magnify savings benefits to the average consumer.

Another factor yet to be

considered by the EPA and DOE is the overall effect of energy-saving

requirements on the durability and expected service life of a mass-market

appliance built to a consumer-level cost standard. For example, a refrigerator

may be made more efficient by the use of more insulative spacing and a

smaller-capacity compressor using electronics to control operation and

temperature. However, this may come at the cost of reduced interior storage (or

increased exterior mass) or a reduced service life due to compressor or electronic

failures. In particular, electronic controls used on new-generation appliances

are subject to damage from shock, vibration, moisture, or power spikes on the

electrical circuit to which they are attached. Critics have pointed out that

even if a new appliance is energy-efficient, any consumer appliance that does

not provide customer satisfaction, or must be replaced twice as often as its

predecessor contributes to landfill pollution and waste of natural resources

used to construct its replacement.

Heating and cooling systems

Energy Star qualified

heat pumps, boilers, air conditioning systems, and furnaces are available. In

addition, cooling and heating bills can be significantly lowered with air

sealing and duct sealing. Air sealing reduces the outdoor air that penetrates a

building, and duct sealing prevents attic or basement air from entering ducts

and lessening the heating/cooling system’s efficiency.

Energy Star

qualified room air conditioners are

at least 10% more energy efficient than the minimum U.S. federal government

standards.

Home electronics

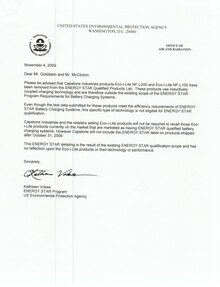

...Eco-i-Lite

NF-L200 and Eco-i-Lite NF-L100 have been removed from the Energy Star Qualified

Products List... It uses 2 watts even when the night light is off and the

flashlight is fully charged or not in the base (when it should be in standby

mode). The Energy Star standard for EPS (External Power Supplies like cell

phone chargers; Tier 2) is to use < 0.5 watts in standby mode.

Energy Star qualified

televisions use 30% less energy than

average. In November 2008, television specifications were improved to limit

on-mode power use, in addition to standby power which is limited by the

current specifications. A wider range of Energy Star qualified televisions will

be available. Other qualified home electronics include cordless phones, battery

chargers, VCRs and external power adapters, most of which use 90% less energy.

Imaging equipment

The Energy Star Program

Requirements for Imaging Products are focused on product families such as

electrophotographic (EP) printers, inkjet printers (e.g., thermal), copiers,

facsimile machines and other imaging equipment including MFD's (multifunctional

devices). Typical Electrical Consumption (TEC) of a product family are measured

and reported against an allowance set by the maximum throughput of the device.

Operation modes (OM) are measured and reported for devices such as inkjet

products against an allowance set by the functions present in the EUT

(equipment under test). Devices that included "adders" such as

Ethernet, on-board memory, wireless, etc. are mathematically "added"

to increase the OM allowance. Recently on February 1, 2011, the EPA/DOE added

the requirement that all products registered under the Energy Star service

mark, must be tested by an AB (Accredited Body) or CB (Certification Body)

Laboratory.

Lighting

The Energy Star is

awarded to only certain bulbs that meet strict efficiency, quality, and

lifetime criteria.

Energy Star

qualified fluorescent lighting uses

75% less energy and lasts up to ten times longer than normal incandescent lights.

Energy Star

Qualified light-emitting diode (LED)

Lighting:

§

Reduces energy costs — uses at

least 75% less energy than incandescent lighting, saving on operating expenses.

§

Reduces maintenance costs —

lasts 35 to 50 times longer than incandescent lighting and about 2 to 5 times

longer than fluorescent lighting. No bulb-replacements, no ladders, no ongoing

disposal program.

§

Reduces cooling costs — LEDs

produce very little heat.

§

Is guaranteed — comes with a

minimum three-year warranty — far beyond the industry standard.

§

Offers convenient features —

available with dimming on some indoor models and automatic daylight shut-off

and motion sensors on some outdoor models.

§

Is durable — won’t break like a

bulb.

To qualify for Energy

Star certification, LED lighting products must pass a variety of tests to prove

that the products will display the following characteristics:

§

Brightness is equal to or greater

than existing lighting technologies (incandescent or fluorescent) and light is

well distributed over the area lighted by the fixture.

§

Light output remains constant over

time, only decreasing towards the end of the rated lifetime (at least 35,000

hours or 12 years based on use of 8 hours per day).

§

Excellent color quality. The shade

of white light appears clear and consistent over time.

§

Efficiency is as good as or better

than fluorescent lighting.

§

Light comes on instantly when turned

on.

§

No flicker when dimmed.

§

No off-state power draw. The fixture

does not use power when it is turned off, with the exception of external

controls, whose power should not exceed 0.5 watts in the off state.

New homes

New homes that meet

strict guidelines for energy efficiency can qualify for Energy Star

certification. An Energy Star qualified home uses at least 15% less energy than

standard homes built to the 2004 International Residential Code (IRC). They

usually include properly installed insulation,

high performance windows, tight construction and ducts, energy efficient

cooling and heating systems, and Energy Star qualified appliances, lighting,

and water heaters.

Further

information: Green

building in the United States

Energy performance ratings

The U.S. EPA's Energy

Star program has developed energy performance rating systems for several

commercial and institutional building types and manufacturing facilities. These

ratings, on a scale of 1 to 100, provide a means for benchmarking the energy

efficiency of specific buildings and industrial plants against the energy

performance of similar facilities. The ratings are used by building and energy

managers to evaluate the energy performance of existing buildings and

industrial plants. The rating systems are also used by EPA to determine if a

building or plant can qualify to earn Energy Star recognition.

For many types of

commercial buildings, you can enter energy information into EPA's free online

tool, Portfolio Manager , and it will calculate a score for your

building on a scale of 1-100. Buildings that score a 75 or greater may qualify

for the Energy Star. Portfolio Manager is an interactive energy management tool

that allows you to track and assess energy and water consumption across your

entire portfolio of buildings in a secure online environment. Whether you own,

manage, or hold properties for investment, Portfolio Manager can help you set

investment priorities, identify under-performing buildings, verify efficiency

improvements, and receive EPA recognition for superior energy performance. Profolio manager online uses

an automated benchmarking tool which can award energy star certificates to the

buildings which have uploaded 12 months of consecutive energy usage data.

Buildings

The number of space

types that can receive the energy performance rating in Portfolio Manager is

expanding and now includes bank/financial institutions,

courthouses, hospitals (acute care and children's), hotels and motels, houses

of worship, K-12 schools, medical offices, offices, residence

halls/dormitories, retail stores, supermarkets, warehouses (refrigerated and

non-refrigerated), data centers, senior care facilities, and wastewater

facilities.

See the technical

descriptions for models used in the rating system at . These documents provide detailed

information on the methodologies used to create the energy performance ratings

including details on rating objectives, regression techniques, and the steps

applied to compute a rating. A 1-100 rating can be generated for ratable space

types by entering building attributes, such as square footage and weekly

operating hours, and monthly energy consumption data into Portfolio

Manager, a free online tool provided by Energy Star. This process is

known as benchmarking and reveals how a building's energy consumption compares

to that of other similar buildings of the same space type, based on a national

average. Earning a rating of 75 or above is the first step towards achieving

the Energy Star for a building.

Energy Star energy

performance ratings have been incorporated into some green buildings standards,

such as LEED for Existing Buildings.

Energy Conservation Building Code - India

Energy Conservation Building Code - India

Industrial facilities

Energy performance

ratings have been released for the following industrial facilities:

Automobile assembly

plants, Cement Plants, Wet Corn Mills, Container glass manufacturing, Flat

glass manufacturing, Frozen fried potato processing plants, Juice processing,

Petroleum refineries, Pharmaceutical manufacturing plants.

Other facilities

Municipal wastewater

treatment plants

Small business award

The U.S. Environmental

Protection Agency (EPA) annually recognizes small businesses that demonstrate

abilities to reduce waste, conserve energy, and recycle. The businesses use

resources and ideas outlined in the Energy Star program. The award was established in

1999.

Controversies

On December 17, 2008,

the EPA Office of the Inspector General released its report on the Energy Star

program. The Inspector General's audit found that the program claims regarding

greenhouse gas reductions were inaccurate and based on faulty data.

Additionally, the IG found that Energy Star program's reported energy savings

were unreliable, and that many of the touted benefits could not be verified.

"Deficiencies included the lack of a quality review of the data collected;

reliance on estimates, forecasting, and unverified third party reporting; and

the potential inclusion of exported items," the report concluded.

Additionally, the American Council for an Energy-Efficient Economy, Consumer Reports, and the trade website

ApplianceAdvisor.com, have released statements

claiming that Energy Star test procedures contained loopholes that allow many

inefficient products to receive Energy Star labels. Specific claims include:

§

U.S. Department of Energy

regulations allowed the manufacturers to test the refrigerators with their

ice-makers turned off, which is not how they are normally used in the home.

However, the Energy Star requirements usually exclude refrigerators that

include an ice maker because of the penetration of the ice dispenser. Some

designs get around this by dispensing the ice into a tray located in the

freezer.

§

Using outdated testing rules and

loose standards to award Energy Star ratings.

§

The program allows manufacturers to

test their own products and only selectively spot-checks the test results they

submit.

§

There are so many individually rated

refrigerator categories that even inefficient product categories (such as

side-by-sides) are certified.

Before the complaints

were raised in 2008, 2006 federal court had required the DOE to update and

tighten misleading Energy Star ratings given to products in almost two dozen

categories, including dishwashers, air conditioners, heaters, furnaces and

clothes dryers. The updates were to settle complaints by 14 states. However,

categories such as room air conditioners and clothes dryers would not be

completed until June 2011.

The U.S. Environmental

Protection Agency had released reports in 2007 and 2008 claiming Energy Star

labels were misleading. Inspector general issued a report that said Energy

Star's savings claims were "not accurate or verifiable." The report

also found that shipment data for Energy Star products were not being

adequately reviewed and in some cases, were based on estimates instead of

actual shipping totals.

Martin Hellman revealed that Energy Star

standby mode requirement can be compromised when an electronic device uses

Download Acquisition Mode (DAM) feature to update TV Guide listing during

standby mode. Hellman first found the feature on Sony KDL-37XBR6.

In March 2010, a report

by the Government

Accountability Office stated that the Energy Star program had

accepted 15 out of 20 bogus products submitted for approval. The Energy Star

program had also qualified four businesses as Energy Star partners, failing to

catch the fact that information on the companies, products and staff were all

fictitious.

Testing vendors

§

Aurora International Testing Laboratory

§

CleanEdison Inc.

www.cleanedison.com

§

ITL

Boulder

§

MET Laboratories,

Inc.

§

TÜV Rheinland Group

§

TÜV SÜD America Inc.

www.TUVamerica.com

§

Underwriters Laboratories, Inc.

www.ul.com